Revolutionizing Metal Forming: The Photovoltaic Rain Gutter Roll Forming Machine

2025-05-01

The photovoltaic rain gutter roll forming machine is a specialized piece of equipment designed to manufacture rain gutters that integrate solar energy technology. This innovative machine plays a crucial role in the metal processing and forming industry, particularly as the demand for sustainable energy solutions grows. By understanding the intricacies of this machinery, professionals can better ap

The photovoltaic rain gutter roll forming machine is a specialized piece of equipment designed to manufacture rain gutters that integrate solar energy technology. This innovative machine plays a crucial role in the metal processing and forming industry, particularly as the demand for sustainable energy solutions grows. By understanding the intricacies of this machinery, professionals can better appreciate its contributions to both energy efficiency and construction practices.

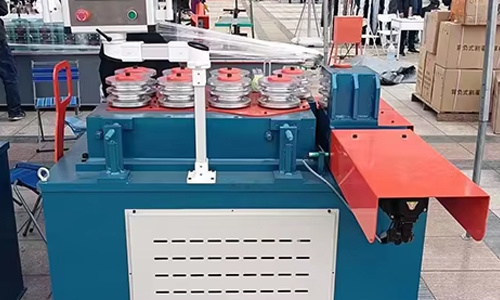

At its core, the photovoltaic rain gutter roll forming machine operates by taking metal coils and converting them into a continuous profile that serves as a rain gutter. This process involves several steps, including feeding the metal coil into the machine, shaping it through a series of rollers, and cutting the finished product to the desired length. The incorporation of photovoltaic cells into these rain gutters allows for energy generation, making them a dual-purpose solution for modern buildings.

One significant advantage of using a photovoltaic rain gutter roll forming machine is its efficiency. The automated nature of the machine reduces labor costs and production time, ensuring that the manufacturing process is both cost-effective and scalable. Additionally, these machines are designed to minimize waste, as they can produce gutters with precise dimensions, leading to a more sustainable use of resources.

Furthermore, incorporating solar technology into rain gutters not only provides an additional energy source for buildings but also enhances their aesthetic appeal. This integration reflects a growing trend in construction towards sustainable building practices, where energy efficiency is prioritized. As such, the role of the photovoltaic rain gutter roll forming machine becomes even more critical, as it helps meet the increasing demand for eco-friendly construction materials.

From a technical standpoint, operators of these machines should be familiar with the various settings and configurations to optimize production. Understanding the properties of different metals, adjusting the roll forming parameters, and maintaining the machinery are all essential skills for ensuring high-quality output.

In conclusion, the photovoltaic rain gutter roll forming machine is a remarkable advancement in the metal forming industry. Its ability to produce functional yet sustainable products positions it as an essential tool for manufacturers looking to innovate and meet modern energy demands. As professionals in the field continue to explore the capabilities of this technology, the future of sustainable construction looks promising. Investing in and utilizing such machinery not only benefits manufacturers but also contributes positively to the environment.

At its core, the photovoltaic rain gutter roll forming machine operates by taking metal coils and converting them into a continuous profile that serves as a rain gutter. This process involves several steps, including feeding the metal coil into the machine, shaping it through a series of rollers, and cutting the finished product to the desired length. The incorporation of photovoltaic cells into these rain gutters allows for energy generation, making them a dual-purpose solution for modern buildings.

One significant advantage of using a photovoltaic rain gutter roll forming machine is its efficiency. The automated nature of the machine reduces labor costs and production time, ensuring that the manufacturing process is both cost-effective and scalable. Additionally, these machines are designed to minimize waste, as they can produce gutters with precise dimensions, leading to a more sustainable use of resources.

Furthermore, incorporating solar technology into rain gutters not only provides an additional energy source for buildings but also enhances their aesthetic appeal. This integration reflects a growing trend in construction towards sustainable building practices, where energy efficiency is prioritized. As such, the role of the photovoltaic rain gutter roll forming machine becomes even more critical, as it helps meet the increasing demand for eco-friendly construction materials.

From a technical standpoint, operators of these machines should be familiar with the various settings and configurations to optimize production. Understanding the properties of different metals, adjusting the roll forming parameters, and maintaining the machinery are all essential skills for ensuring high-quality output.

In conclusion, the photovoltaic rain gutter roll forming machine is a remarkable advancement in the metal forming industry. Its ability to produce functional yet sustainable products positions it as an essential tool for manufacturers looking to innovate and meet modern energy demands. As professionals in the field continue to explore the capabilities of this technology, the future of sustainable construction looks promising. Investing in and utilizing such machinery not only benefits manufacturers but also contributes positively to the environment.

Key words:

RELATED INFORMATION

A customer from Inekhusko, Russia, took a 10-hour flight with multiple transfers to visit our factory and inspect the equipment they had previously ordered from our company.Our foreign trade staff warmly received the customer.

2025-04-24

Photovoltaic bracket equipment is a special bracket planned for the placement, installation.

2024-05-22

The control method of greenhouse pipe bender and the CNC processing of pipe bender

The greenhouse pipe bender has a fuel tank cap. We can take advantage of the environment where the oil in.

2024-05-22