Enhancing Durability: The Role of Photovoltaic Rain Gutter Roll Forming Machines

2025-04-28

Enhancing Durability: The Role of Photovoltaic Rain Gutter Roll Forming Machines

Table of Contents

1. Introduction to Photovoltaic Rain Gutter Roll Forming Machines

2. Understanding Roll Forming Technology

3. Benefits of Photovoltaic Rain Gutter Systems

4. The Mechanical Design of Roll Forming Machines

5. Environmental Impact and Sustainability

6. Automation in Roll Formin

Enhancing Durability: The Role of Photovoltaic Rain Gutter Roll Forming Machines

Table of Contents

- 1. Introduction to Photovoltaic Rain Gutter Roll Forming Machines

- 2. Understanding Roll Forming Technology

- 3. Benefits of Photovoltaic Rain Gutter Systems

- 4. The Mechanical Design of Roll Forming Machines

- 5. Environmental Impact and Sustainability

- 6. Automation in Roll Forming Processes

- 7. Maintaining Quality and Performance

- 8. Future Trends in Photovoltaic Rain Gutter Technology

- 9. Conclusion

- 10. Frequently Asked Questions

1. Introduction to Photovoltaic Rain Gutter Roll Forming Machines

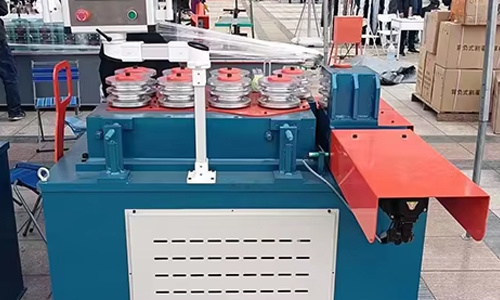

The advent of **photovoltaic rain gutter roll forming machines** marks a significant evolution in the manufacturing of rainwater systems. These machines are designed to create seamless gutter profiles while seamlessly integrating solar technology, which enhances their durability and efficiency. By combining traditional roll forming techniques with innovative photovoltaic elements, manufacturers can produce rain gutters that not only collect rainwater but also generate renewable energy.

2. Understanding Roll Forming Technology

Roll forming is a continuous bending operation in which a long strip of metal is passed through a series of rollers to create a desired cross-sectional profile. The process is highly efficient and can be tailored for a variety of metal types, including steel, aluminum, and copper. Key features of roll forming technology include:

2.1 Advantages of Roll Forming

- **High Production Rates**: Roll forming machines can produce thousands of feet of finished product in a short period.

- **Minimal Waste**: The process utilizes nearly 100% of the raw material, resulting in less scrap metal.

- **Consistent Quality**: Automated setups ensure uniformity and high standards in the finished product.

2.2 Applications in Metal Fabrication

Photovoltaic rain gutter roll forming machines are primarily used in the construction and architectural sectors, where durability and functionality are paramount. They are ideal for producing gutters that withstand harsh environmental conditions while maintaining aesthetic appeal.

3. Benefits of Photovoltaic Rain Gutter Systems

Photovoltaic rain gutters offer numerous advantages that enhance both their functionality and durability:

3.1 Energy Generation

By integrating solar panels into gutter systems, these products generate clean energy for residential and commercial properties. This can significantly reduce energy costs and reliance on fossil fuels.

3.2 Enhanced Durability

The use of high-quality materials and advanced manufacturing processes results in gutters that resist corrosion, rust, and other forms of wear. This longevity translates to lower maintenance costs and fewer replacements.

3.3 Environmental Benefits

Incorporating sustainable technologies helps reduce the carbon footprint of buildings. Photovoltaic rain gutters contribute to energy efficiency and support eco-friendly construction practices.

4. The Mechanical Design of Roll Forming Machines

The mechanical design of photovoltaic rain gutter roll forming machines plays a crucial role in the production process. Key components include:

4.1 Roll Set Configuration

The roll set configuration is essential for determining the final profile of the gutter. Customizable roll sets allow for versatility in design, ensuring products meet specific client requirements.

4.2 Drive System

A robust drive system is necessary for maintaining consistent speed and torque throughout the forming process. Gear-driven or chain-driven systems are typically used to provide reliable performance.

4.3 Control Systems

Modern roll forming machines are equipped with advanced control systems that allow for precise adjustments. This technology ensures that even slight variations in material thickness or composition can be accommodated without sacrificing quality.

5. Environmental Impact and Sustainability

The production and installation of photovoltaic rain gutter systems have a positive impact on environmental sustainability. By utilizing renewable energy sources, these systems help mitigate climate change and promote responsible resource use.

5.1 Sustainable Manufacturing Practices

Manufacturers are increasingly adopting sustainable practices, such as recycling scrap metal and using eco-friendly lubricants to reduce environmental harm during production.

5.2 Long-Term Benefits

The durability of photovoltaic rain gutters means that they will last longer than traditional systems, reducing the need for frequent replacements and lessening overall waste.

6. Automation in Roll Forming Processes

Automation is transforming the roll forming industry by increasing efficiency and reducing labor costs. Advanced technologies allow for:

6.1 Real-Time Monitoring

Automated systems can monitor production in real-time, providing feedback on quality and output. This ensures that any issues can be addressed promptly, maintaining the integrity of the manufacturing process.

6.2 Reduced Labor Costs

With automation, the need for manual labor decreases, enabling manufacturers to allocate resources more effectively. This can lead to increased profitability and reduced operational costs.

7. Maintaining Quality and Performance

Quality control is vital in the production of photovoltaic rain gutters. Key strategies include:

7.1 Regular Inspections

Routine inspections during the manufacturing process help identify any defects early, ensuring that only high-quality products reach the market.

7.2 Testing for Durability

Conducting stress tests and durability assessments ensures that gutters can withstand various environmental conditions, from heavy rain to extreme temperatures.

8. Future Trends in Photovoltaic Rain Gutter Technology

The future of photovoltaic rain gutter technology looks promising, with several trends emerging:

8.1 Innovations in Solar Technology

Advancements in solar panel efficiency and design will likely enhance the performance of photovoltaic gutters, making them even more attractive for consumers.

8.2 Integration with Smart Home Systems

As smart home technology becomes more prevalent, integrating photovoltaic rain gutters with home automation systems will provide users with greater control over their energy consumption and management.

8.3 Expanding Market Opportunities

The growing demand for sustainable construction solutions will drive further innovation in photovoltaic rain gutters, opening new markets and opportunities for manufacturers.

9. Conclusion

Photovoltaic rain gutter roll forming machines represent a significant leap forward in both durability and sustainability within the metal fabrication industry. By merging traditional roll forming techniques with cutting-edge solar technology, these machines produce gutters that not only function effectively but also contribute to renewable energy generation. As the world increasingly prioritizes sustainability and environmental responsibility, the adoption of photovoltaic rain gutters will likely become standard practice in modern construction.

10. Frequently Asked Questions

10.1 What are photographic rain gutter roll forming machines?

Photovoltaic rain gutter roll forming machines are specialized equipment designed for manufacturing rain gutters that incorporate solar technology for energy generation.

10.2 How do these machines enhance durability?

These machines utilize high-quality materials and advanced manufacturing techniques to produce gutters that resist corrosion and wear, resulting in longer-lasting products.

10.3 What materials can be used in roll forming?

Commonly used materials include steel, aluminum, and copper, all of which can be effectively shaped using roll forming technology.

10.4 Are photovoltaic rain gutters cost-effective?

Yes, while the initial investment may be higher, the long-term energy savings and reduced maintenance costs make them a financially viable option.

10.5 What trends are shaping the future of photovoltaic rain gutters?

Emerging trends include advancements in solar technology, integration with smart home systems, and the growing demand for sustainable construction solutions.

This article has provided a comprehensive overview of the role of photovoltaic rain gutter roll forming machines in enhancing durability and sustainability in the manufacturing process. Emphasizing quality, efficiency, and environmental responsibility, these machines are poised to lead the way in modern metal fabrication.

Key words:

RELATED INFORMATION

A customer from Inekhusko, Russia, took a 10-hour flight with multiple transfers to visit our factory and inspect the equipment they had previously ordered from our company.Our foreign trade staff warmly received the customer.

2025-04-24

Photovoltaic bracket equipment is a special bracket planned for the placement, installation.

2024-05-22

The control method of greenhouse pipe bender and the CNC processing of pipe bender

The greenhouse pipe bender has a fuel tank cap. We can take advantage of the environment where the oil in.

2024-05-22