Contact Us

Electronic E-mail

info@gcrollforming.com

Telephone:

+8615233789270

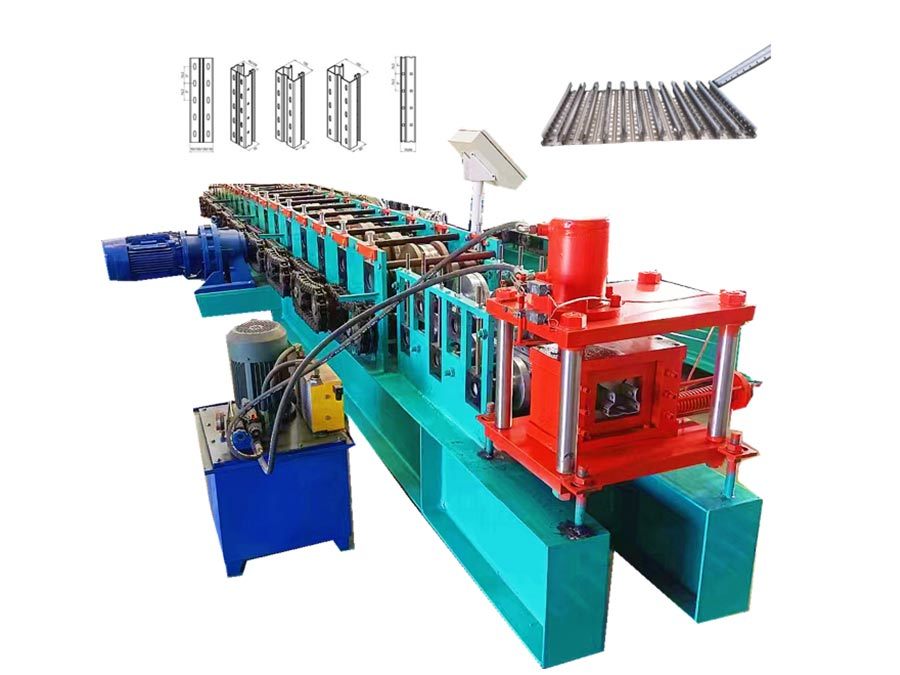

Automatic Highway Guardrail Roll Forming Machine with w Beam Steel High-Tech w Beam Steel Highway Guardrail Machine

Keywords:

W beam guardrail repairing machine

Category:

Introduction

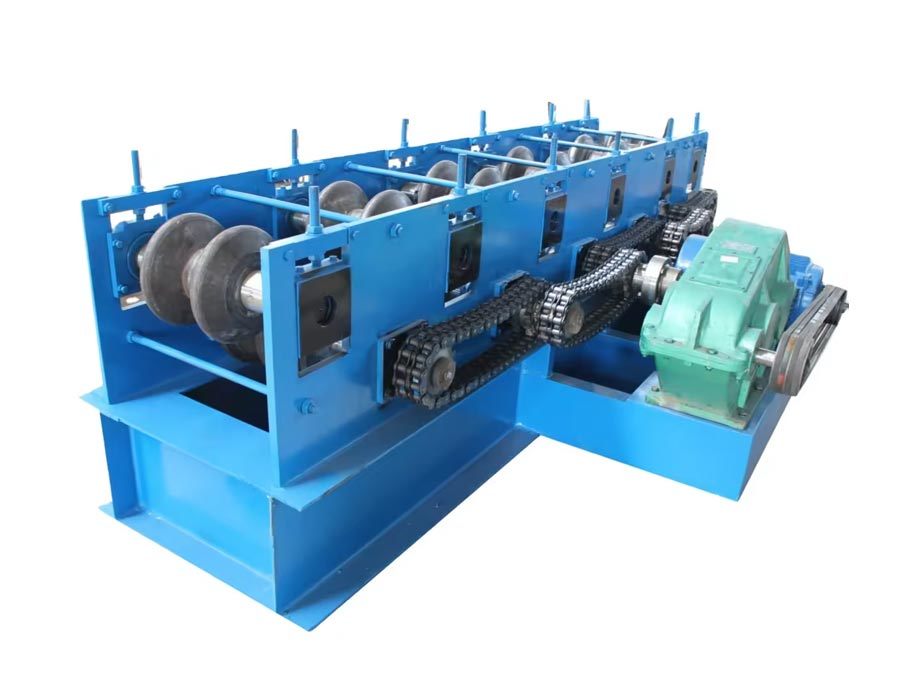

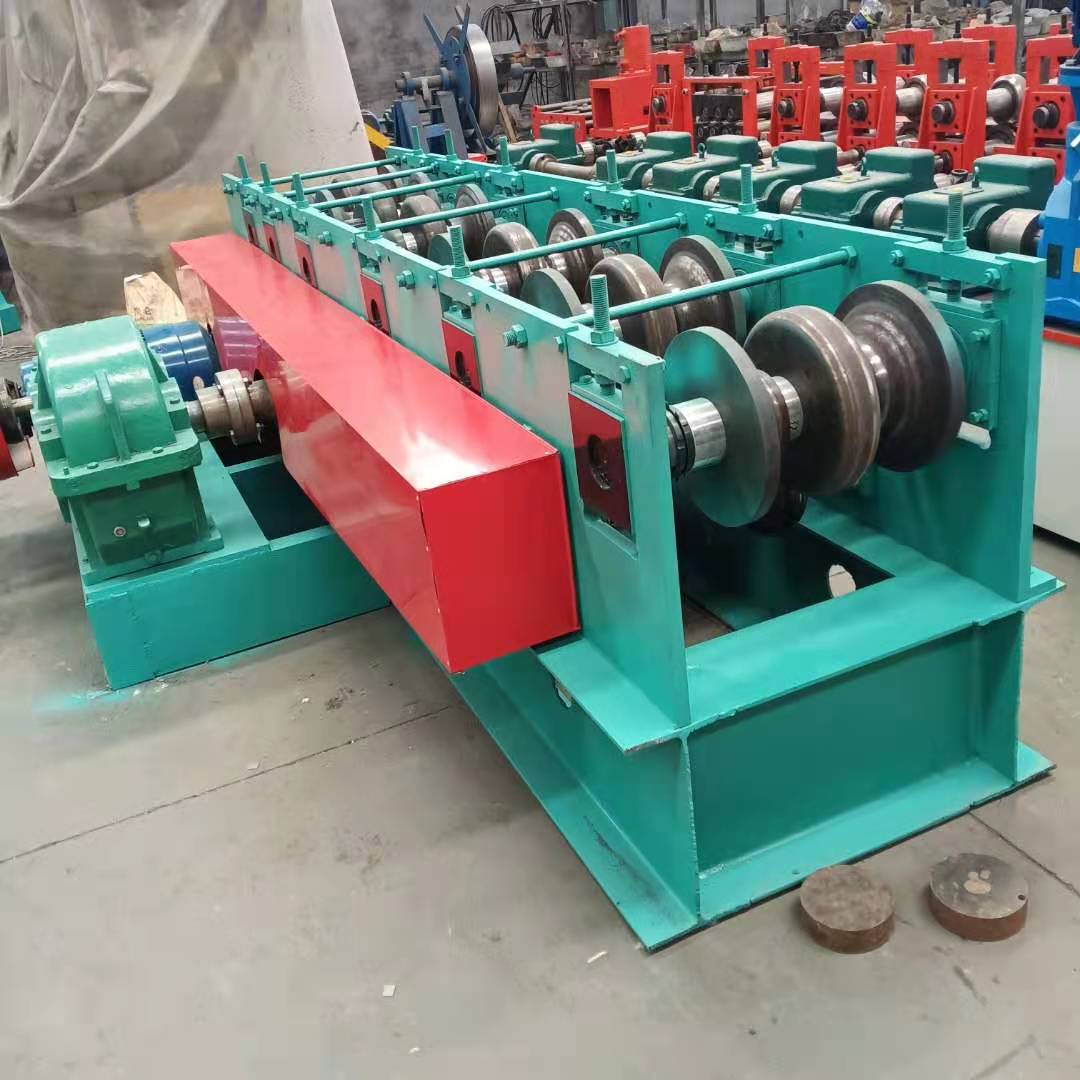

Table of main technical parameters of 6-row guardrail plate correction machine

|

【Function parameters of guardrail plate correction machine】 |

|

|

Board size |

Customized according to the tile type provided by the customer |

|

Device size |

3.5m*1.8m*1.1m |

|

Roller forming row number |

6 rows (2 rows for correction, 4 rows for straightening) |

|

Repair thickness |

4.0mm |

|

Roller diameter |

Ø90 |

|

Shaft Material |

45# quenching and tempering finishing |

|

Wheel material |

GCr15 quenching and finishing |

|

Host power |

22KW+500PM (speed ratio 48.57) |

|

frame |

400H Steel |

|

Electronic Control |

Forward and reverse electric control cabinet |

|

Wall Panels |

25mm high strength plate |

|

Production speed |

4-12m/min |

|

Transmission mode |

1.5 inch double chain drive |

|

Note: The equipment needs to be operated by personnel who have received training |

|

Picture display:

Quality W beam guardrail repairing machines are available from China manufacturers, offering reliable solutions for road safety maintenance. These customized machines ensure efficient repairs of damaged guardrails, restoring structural integrity. For companies seeking the cheapest and most cost-effective products, wholesale options are on sale. Trusted suppliers and factories in China provide guardrail repair machines with competitive prices and quality assurance.

Looking for a cheap W beam guardrail repairing machine? Chinese manufacturers offer customized and quality machines at a wholesale price, ensuring smooth operations for road maintenance projects. With advanced technology and efficient production processes, companies in China deliver reliable and durable products. On-sale options are available from reputable factories and suppliers, making it easy to find the best solution for your infrastructure needs.

Get the best deals on quality W beam guardrail repairing machines from China manufacturers. With wholesale prices and customized features, these machines are designed for effective guardrail maintenance and repair. Suppliers and factories in China provide reliable products on sale, ensuring long-term performance and cost-efficiency. Whether you are a construction company or a road safety management team, choose from the top manufacturers in China for your guardrail repair needs.

Debugging and teaching: The manufacturer is responsible for the debugging of the equipment. In addition to debugging the equipment, the debugger needs to teach Party A about the operation, use and daily maintenance. Party B is responsible for the wages and round-trip expenses of the debugging personnel, and Party A is responsible for the room, board and transportation of the debugging personnel during the debugging period.

Quality assurance: The free warranty period of the equipment and products provided by our company is one year from the date of signing the contract. During the warranty period, if the equipment and products provided by our company are faulty or damaged due to quality problems, after receiving the notice from Party A, the purchaser will arrange maintenance personnel in time to undertake testing, maintenance and related matters. If the damage caused by improper human operation is not covered by the free warranty. After the one-year free warranty period, the two parties can agree on the after-sales service separately. In principle, the manufacturer only charges the maintenance cost.

Advantage

Guangchi Machinery allows you to choose with confidence

Cangzhou Guangchi Machinery co., Ltd. has been engaged in the manufacture of tile press, greenhouse skeleton production equipment,

high-speed guardrail production equipment and other cold-formed molding equipment and products for fifteen years.

Experience

We have nearly 15 years of experience in equipment manufacturing.

Patent

We have our own patented technology and the technology are widely used in this industry.

Quality

We have our own quality inspection team, every machine will be tested and evaluated.

Professionalism

We have a professional design team and over 20 skilled workers.We have 5 engineers to guide the assembly and debugging of the equipment.

Factory

Why choose us?

1. We have factory and provide direct service and lower price.

2. Our boss is a professional designer who graduated from university . She has more than 20 years mechanical design experiences which can provide you professional suggestions about your products, and help you get top sales.

3. We' ve provided kinds of metal machines to many customers including many international trade companies.

Previous:

Get Quote

*Contact us now, starting from the first communication!