Contact Us

Electronic E-mail

info@gcrollforming.com

Telephone:

+8615233789270

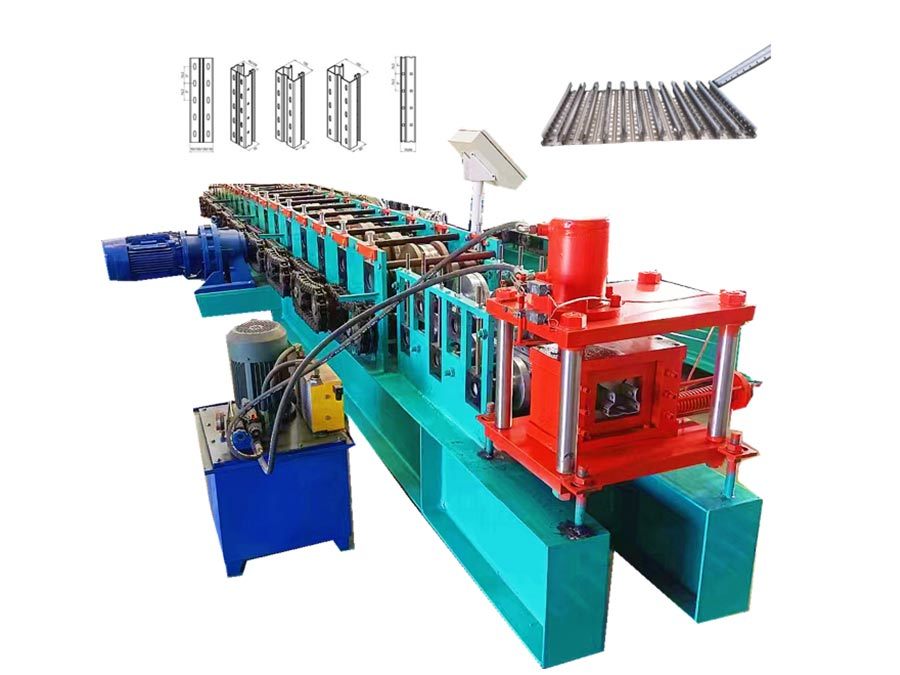

Three beam guardrail flattening machine

Keywords:

Wholesale Three beam guardrail flattening machine Price

Category:

Introduction

In the realm of construction and infrastructure maintenance, ensuring the integrity and safety of guardrails is paramount. The Best Three Beam Guardrail Flattening Machine emerges as a game-changing solution, meticulously designed to restore damaged or misshapen guardrails to their optimal condition with unparalleled precision and efficiency. Our machine stands out not just for its advanced technology but also for its customizable features that cater to diverse project needs.

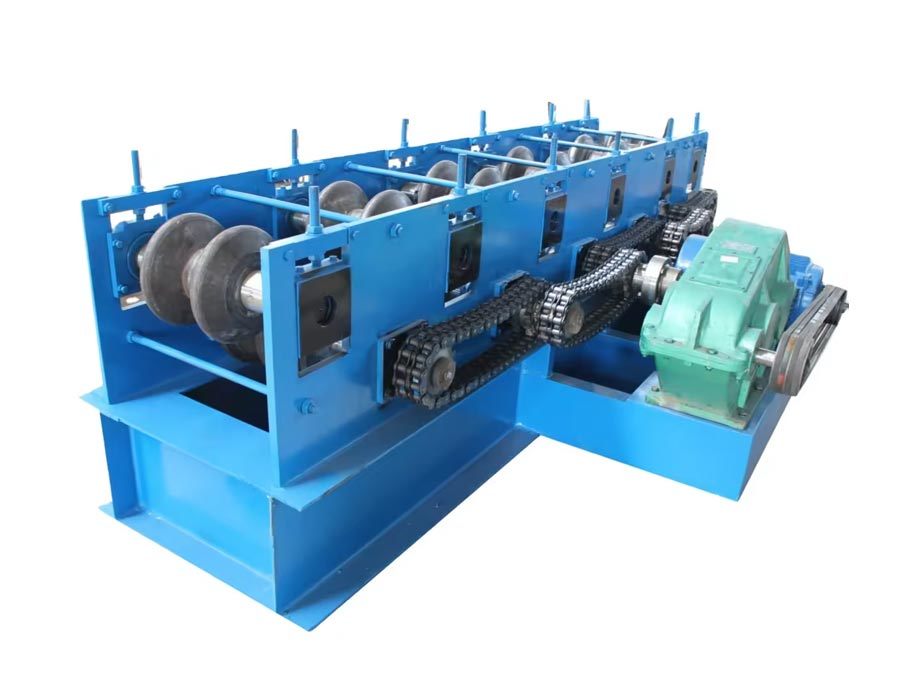

At the heart of our flattening machine lies a robust three-beam design, which guarantees superior stability during operation. This unique configuration allows for even pressure distribution across the width of the guardrail, ensuring a flawless finish every time. Unlike conventional models, our machine's three-beam system minimizes deflection and maximizes contact area, resulting in faster processing without compromising on quality.

We understand that no two projects are alike. That's why we offer comprehensive customization options for our Three Beam Guardrail Flattening Machine. From adjusting the beam spacing to accommodate various guardrail profiles to integrating specialized rollers for different materials, we tailor each machine to match your specific requirements. Whether you're working with steel, aluminum, or other metal alloys, our experts will configure the perfect setup for you.

Detailed technical parameters of the equipment of the two-wave and three-wave guardrail plate flattening all-in-one machine

|

Size |

Two waves + three waves (national standard) |

|

Roller forming row number |

8 rows + 11 rollers for leveling |

|

Repair plate thickness |

4.5mm |

|

Roller diameter |

φ105mm |

|

Leveling roller |

11 rollers φ125mm |

|

Shaft Material |

45# quenching and tempering finishing |

|

Wheel material |

Gcr15 quenching and finishing |

|

Host power |

30KW+650PM reducer |

|

frame |

400H Steel |

|

Electronic Control |

Forward and reverse electric control cabinet |

|

Wall Panels |

80mm high strength plate |

|

Transmission mode |

2 inch double chain + gear drive |

|

Machine size |

Length 5.5m Width 1.5m Height 1.2m |

|

weight |

12 tons |

Advantage

Guangchi Machinery allows you to choose with confidence

Cangzhou Guangchi Machinery co., Ltd. has been engaged in the manufacture of tile press, greenhouse skeleton production equipment,

high-speed guardrail production equipment and other cold-formed molding equipment and products for fifteen years.

Experience

We have nearly 15 years of experience in equipment manufacturing.

Patent

We have our own patented technology and the technology are widely used in this industry.

Quality

We have our own quality inspection team, every machine will be tested and evaluated.

Professionalism

We have a professional design team and over 20 skilled workers.We have 5 engineers to guide the assembly and debugging of the equipment.

Factory

Why choose us?

1. We have factory and provide direct service and lower price.

2. Our boss is a professional designer who graduated from university . She has more than 20 years mechanical design experiences which can provide you professional suggestions about your products, and help you get top sales.

3. We' ve provided kinds of metal machines to many customers including many international trade companies.

Get Quote

*Contact us now, starting from the first communication!