Contact Us

Electronic E-mail

frank@gcrollforming.com

Telephone:

+8615233789270

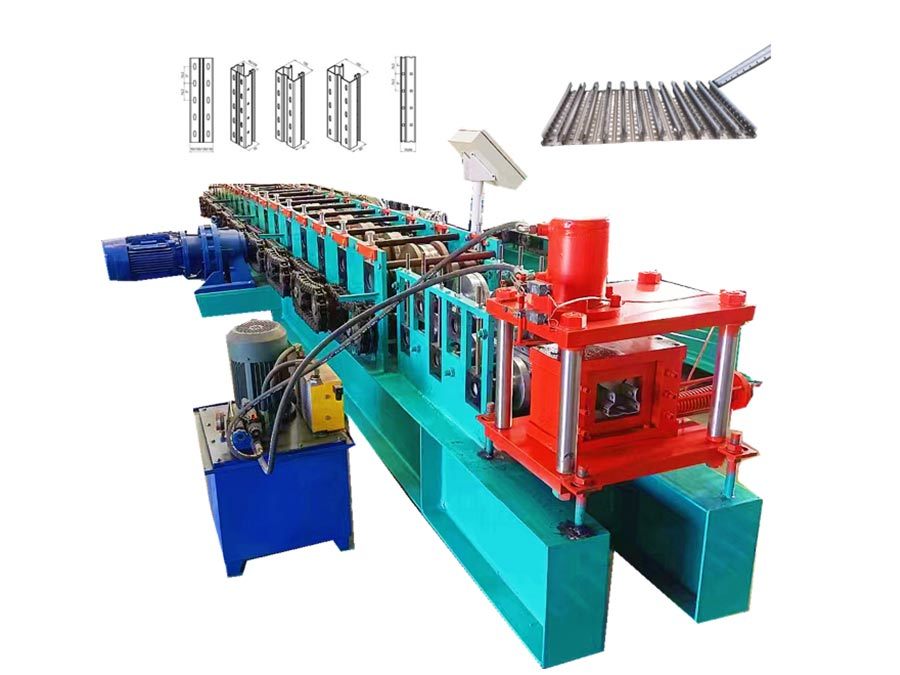

Highway guardrail forming machine

Keywords:

Category:

Introduction

Equipment board type

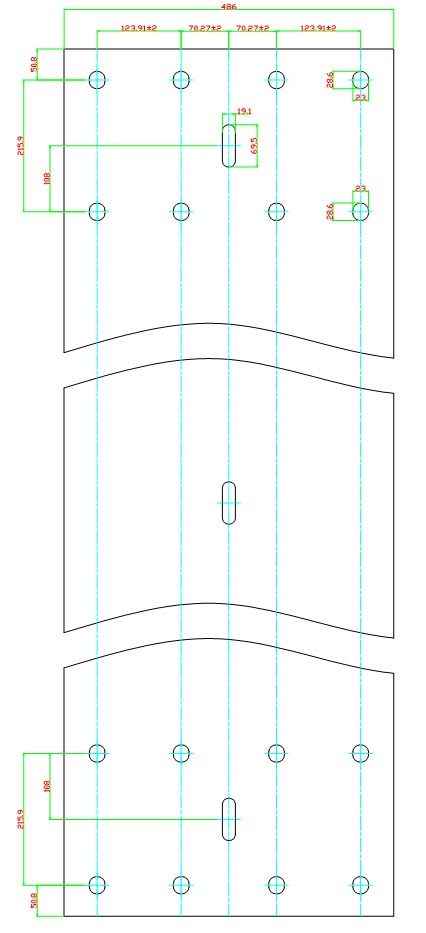

Two waves: thickness 3.0-4.0mm

Material: Galvanized sheet, yield strength 483Mpa

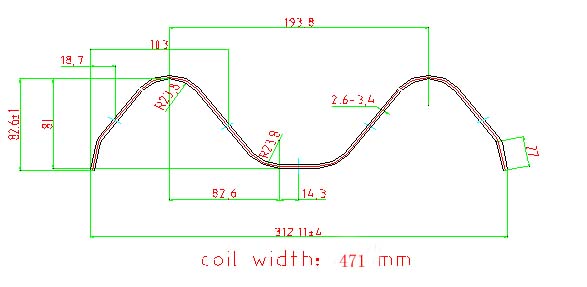

Dimensional tolerance: 312.11±4mm

Punching distance tolerance: ±1.5mm

Finished product length: 4320mm

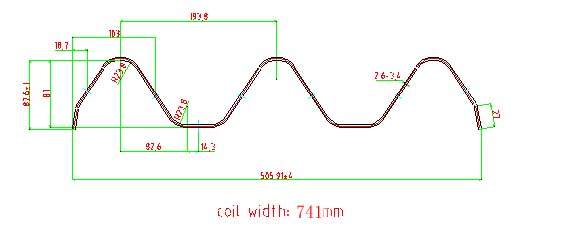

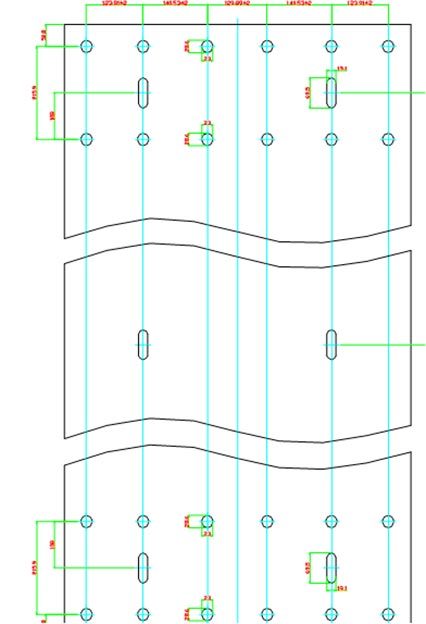

Three waves:

Thickness 3.0-4.0mm

Material: Galvanized sheet, yield strength 483Mpa

Dimensional tolerance: 505.91±4mm

Punching distance tolerance: ±1.5mm

Finished product length: 4320mm

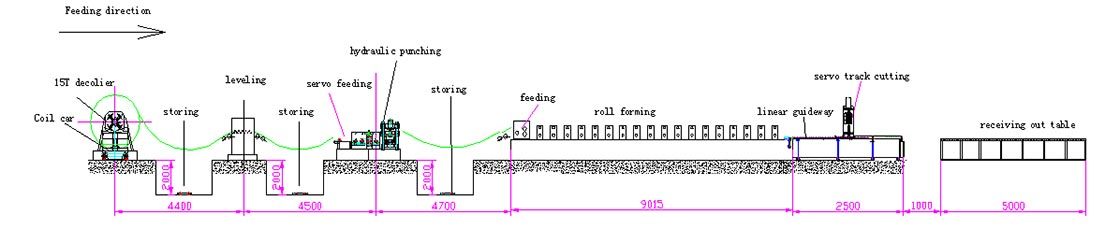

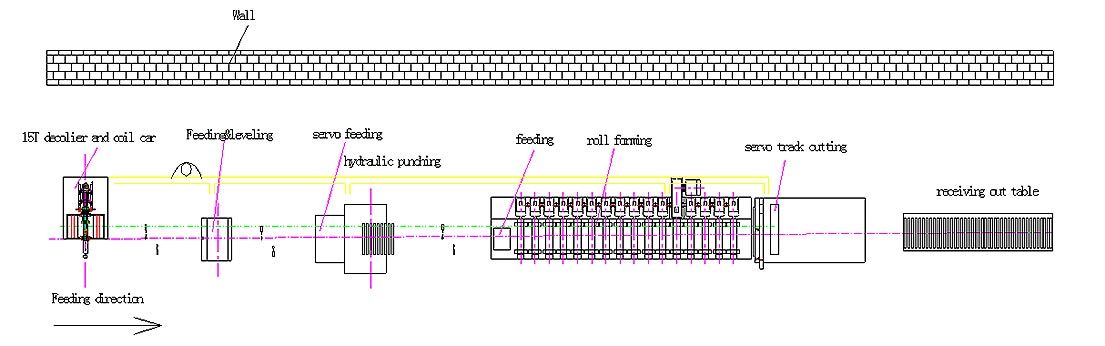

Equipment process: pay attention to the direction of work

Discharge—storage-feeding & leveling—storage—punching and shearing—storage—feeding—forming-8m discharge table

|

Parameters of a material rack |

| 1.Material rack type: 10T hydraulic material rack (with a box like a guardrail plate, and 10 tons for the shaft) |

| 2.Motor power and speed ratio: 7.5kw hydraulic station power 5.5kw speed ratio 1:43 |

| 3.With or without pressure: yes |

| 4.Tensioning range: 470-620mm |

| 5.Product expansion: 1000mm |

| 6.Cylinder size: 120mm |

| 7.Shaft diameter: 100mm |

| 8.Electronic control system: Taiwan Delta |

| 9.Rack voltage: 380V, 60HZ, 3-phase |

| 10.Machine color: company color |

| 11.Quantity: 1 |

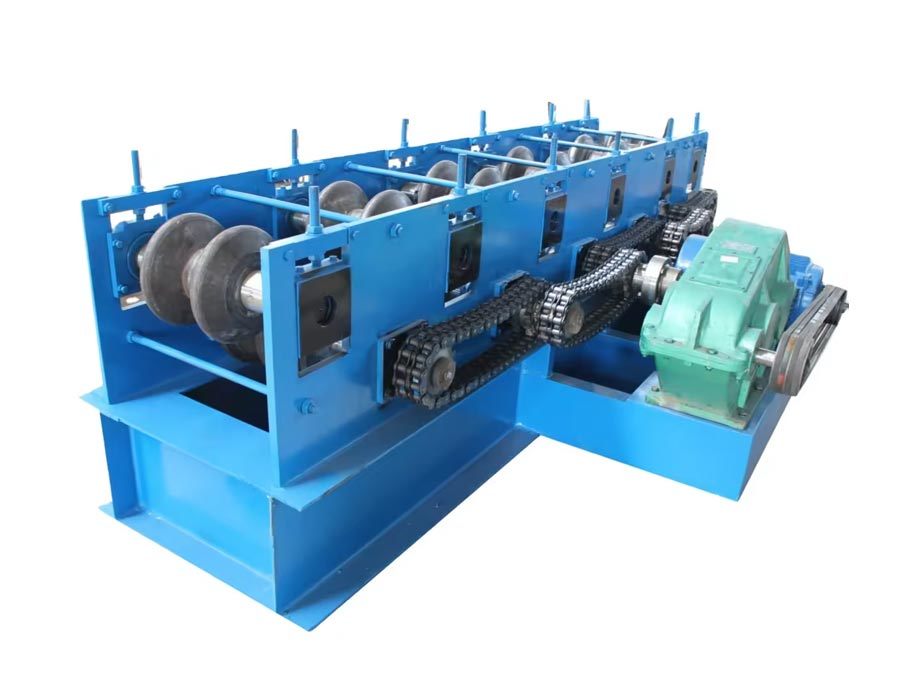

| Two feeding & leveling parameters |

| 1.Feed type: size adjustable |

| 2.Feeding range: according to the version |

| 3.Feeding & guide roller: diameter 100mm, 45 steel material, |

| 4.Leveling roller: 7-roller leveling, 45-steel quenching and tempering treatment, the spacing of the leveling roller is increased to 20 mm |

| 5.Power: 7.5kw, speed ratio 1:23 |

| 6.Speed: 0-10m/min, the speed is adjusted by Delta inverter |

| 7 Quantity: 1 |

| Three feeding & punching parameters |

| 1.Feeding type: hydraulic feeding |

| 2.Punching and shearing: 2 sets of molds |

| 3.Hydraulic power: 15kw |

| 4.Hydraulic pressure: 35MPa adjustable |

| 5.Punching is controlled by PLC |

| 6.Machine color: host company color |

| 7.Quantity: 1 |

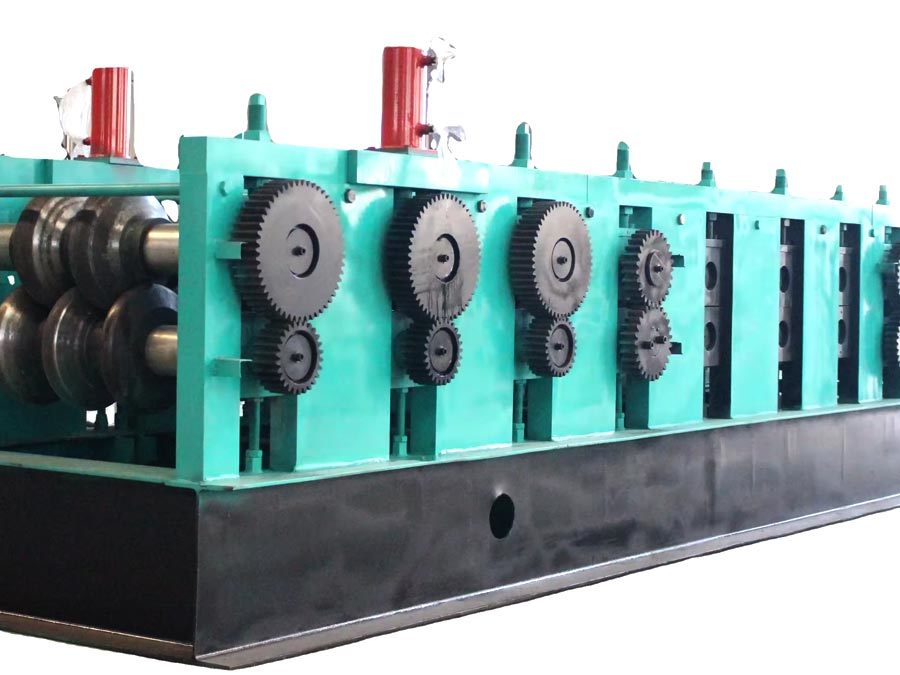

| Four feed & host & shear parameters |

| 1.Number of roll groups: 18 channels |

| 2.Roll material: Gcr15 quenched |

| 3.Spindle material: 45 steel |

| 4.Spindle outer circle: 90mm |

| 5.Arch structure: guide post |

| 6.Frame structure: H-shaped steel welded, there are level adjustment screws on the frame |

| 7.Host appearance: There are two emergency stop switches on the host |

| 8.Feeding method: hand-cranked |

| 9. Feed roller: diameter 105mm, 45 steel material, polished chrome-plated HRC58-62° |

| 10.Number of guide groups: |

| 11.Main motor model, power, speed ratio: 45KW, speed ratio 1:35 |

| 12.Motor-pump device: |

| 13.Electro-hydraulic station power: 22kW, 35MPa |

| 14.Number of electronic valve groups: 3 groups |

| 15.Cylinder size: |

| 16.Shear material: CR12 heat treatment 58-60° |

| 17shearing method: flat hydraulic shearing |

| 18.Pressing material: galvanized sheet, 483mpa |

| 19.Thickness of pressed material: 2.6-3.0mm |

| 20.Pressing material expansion: 471mm & 741mm |

| 21.Transmission method: gearbox transmission |

| 22.Gearbox size: 230 model |

| 23.Number of gearboxes: 17 sets |

|

27.Equipment voltage: 380V, 60HZ, 3-phase |

| 28.Machine color: host company color |

|

29.Two waves for three waves: just replace the last three (the last three should be made into a whole, easy to replace) as shown in the figure below.:

|

| Four discharge parameters |

| 1.Discharge type: ordinary discharge |

| 2.Feed length: 4320mm |

| 3.Dimensions: About 10 meters long, with self-matching width and height |

|

4.The roller should be denser, as shown in the figure: |

| 4..Machine color: company color |

| 5.Number of discharge tables: 1 |

| Five electrical parameters |

| 1.Main motor model, power, speed ratio: 45kw |

| 2.Motor-pump device: 22kw |

| 3.Electro-hydraulic station power: 22kw, 35MPa, |

| 4.Number of electronic valve groups: 3 groups |

| 5.Cylinder size: |

| 6.Electronic control system: Delta PLC |

| 7.Inverter: Delta |

| 8.Touch screen: Delta |

| 9.Encoder: Omron |

| 10.Motors: All motors are Delta |

Advantage

Guangchi Machinery allows you to choose with confidence

Cangzhou Guangchi Machinery co., Ltd. has been engaged in the manufacture of tile press, greenhouse skeleton production equipment,

high-speed guardrail production equipment and other cold-formed molding equipment and products for fifteen years.

Experience

We have nearly 15 years of experience in equipment manufacturing.

Patent

We have our own patented technology and the technology are widely used in this industry.

Quality

We have our own quality inspection team, every machine will be tested and evaluated.

Professionalism

We have a professional design team and over 20 skilled workers.We have 5 engineers to guide the assembly and debugging of the equipment.

Factory

Why choose us?

1. We have factory and provide direct service and lower price.

2. Our boss is a professional designer who graduated from university . She has more than 20 years mechanical design experiences which can provide you professional suggestions about your products, and help you get top sales.

3. We' ve provided kinds of metal machines to many customers including many international trade companies.

Previous:

Next:

Get Quote

*Contact us now, starting from the first communication!