Contact Us

Electronic E-mail

info@gcrollforming.com

Telephone:

+8615233789270

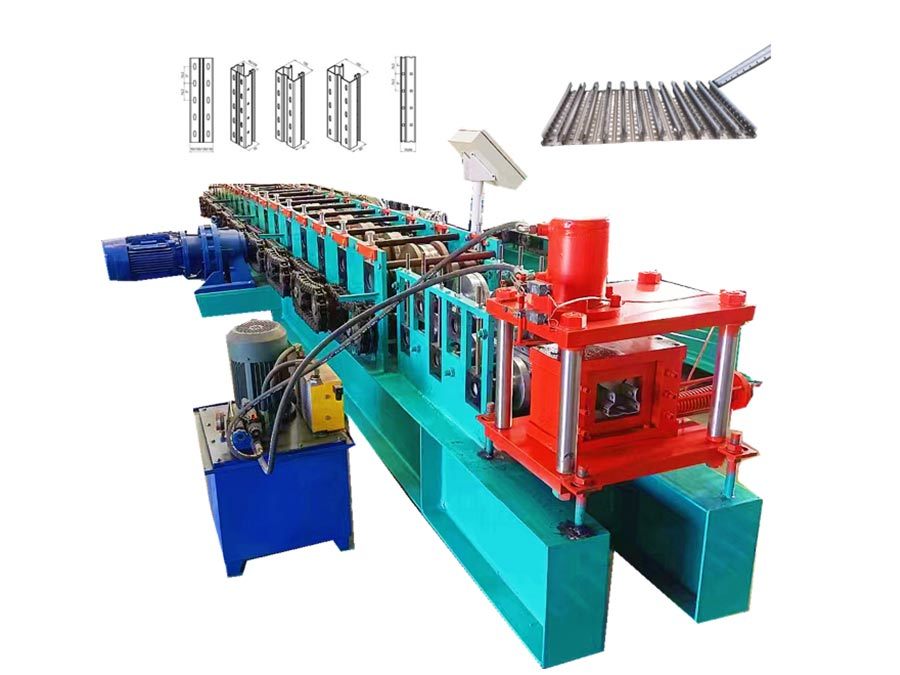

Solar Photovoltaic C-shaped steel strut channel roll forming machine

Keywords:

Production Equipment

Guangchi Machinery

Category:

Introduction

25m C-type photovoltaic bracket equipment

Equipment technical parameters (gear box universal joint gantry arch type):

1.Shaft diameter 80mm, 40Cr quenching and tempering treatment;

2.The thickness of the body plate is 25mm, precision milling,

3.Bearing 314NU;

4.Reducer 22KW-K107 (hard gear reducer) 1 set;

5.14 rows of pressure rollers are formed.The production model is 60-120mmC steel

6.Main engine power Kaiping (upper 3, lower 4 axles);

7.The cutting is: servo tracking, non-stop hydraulic mold cutting; equipped with a hydraulic pumping station of 7.5KW, and a servo motor of 3.8KW.Randomly equipped with 1 set of blades, and an additional mold knife is purchased for 2,000 yuan/set.

9.The electronic control is automatic control by frequency conversion PLC;

10.The roller material is Cr12 mold steel, vacuum quenched; fine turning.

11.Correction shaft: worm gear type;

12.Transmission method: 170 gearbox universal joint transmission;

13.The main frame is welded with steel plate;

14.The weight of the unit is about 9T and the size is about 9X2X1.3m; the total weight of the unit is about 10 tons.

16.Randomly equipped with a 6-meter passive feeding rack (no power).

17.Platen thickness 2-3mm

18. The production speed of the unit is 30 meters/min

19. The thickness of the cast steel gantry arch is 55mm.

20.The equipment is suitable for galvanized steel strips, black iron steel strips, zinc-aluminum-magnesium steel strips.

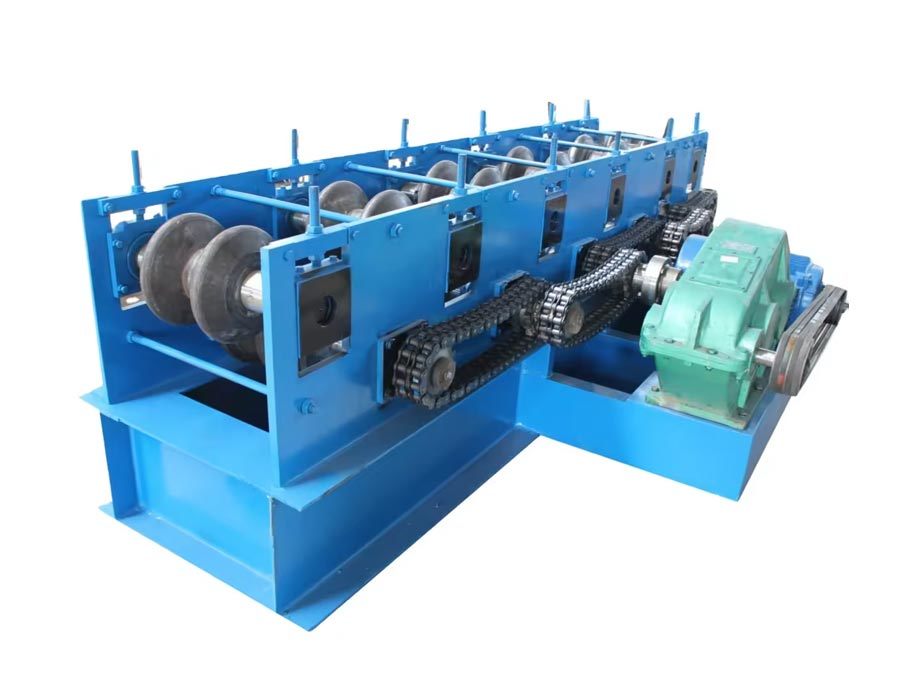

Photovoltaic type C equipment (40 meters/min) technical parameters (gearbox transmission)

1.Shaft diameter Ø80mm, No. 45 quenching and tempering treatment;

2.The thickness of the cast steel arch is 50mm.

3.Double NU212 cylindrical roller bearings.

4.Motor 15KW+K97*2 sets;

5.16 rows of pressure rollers; gearbox drive

6.Main engine power Kaiping (upper 3, lower 4 axles);

7.The cutting is: non-stop hydraulic mold cutting (with a set of blades with the equipment); servo tracking non-stop hydraulic mold cutting; equipped with a hydraulic pumping station 7.5KW, servo motor 3.8KW.Randomly equipped with 1 set of blades, and an additional mold knife is purchased for 2500 yuan/set.

8.The electronic control is automatic control by frequency conversion PLC;

9.The roller material is Cr12, vacuum quenched;

10.Correction axis: universal straightening axis;

11.Transmission method: 170 gearbox (8M) transmission;

12.The main frame is welded with steel plate; the thickness of the fuselage plate is 25mm, and the positioning keyway is processed by precision milling.

13.The weight of the main unit is about 8T and the size is about 9mX2mX1.1m;

14.Pressing thickness 1.5-3.0mm

15.Type C model has a bottom width of 50-160, a waist height of 40-80, and a small side of 15-20.

16.Randomly equipped with a 6-meter passive feeding rack (no power).

17.Platen thickness 1.5-3.0mm

18.Unit production speed 40 meters/min

19.The equipment is suitable for galvanized steel strips, black iron steel strips, zinc-aluminum-magnesium steel strips.

Advantage

Guangchi Machinery allows you to choose with confidence

Cangzhou Guangchi Machinery co., Ltd. has been engaged in the manufacture of tile press, greenhouse skeleton production equipment,

high-speed guardrail production equipment and other cold-formed molding equipment and products for fifteen years.

Experience

We have nearly 15 years of experience in equipment manufacturing.

Patent

We have our own patented technology and the technology are widely used in this industry.

Quality

We have our own quality inspection team, every machine will be tested and evaluated.

Professionalism

We have a professional design team and over 20 skilled workers.We have 5 engineers to guide the assembly and debugging of the equipment.

Factory

Why choose us?

1. We have factory and provide direct service and lower price.

2. Our boss is a professional designer who graduated from university . She has more than 20 years mechanical design experiences which can provide you professional suggestions about your products, and help you get top sales.

3. We' ve provided kinds of metal machines to many customers including many international trade companies.

Previous:

Get Quote

*Contact us now, starting from the first communication!