Contact Us

Electronic E-mail

info@gcrollforming.com

Telephone:

+8615233789270

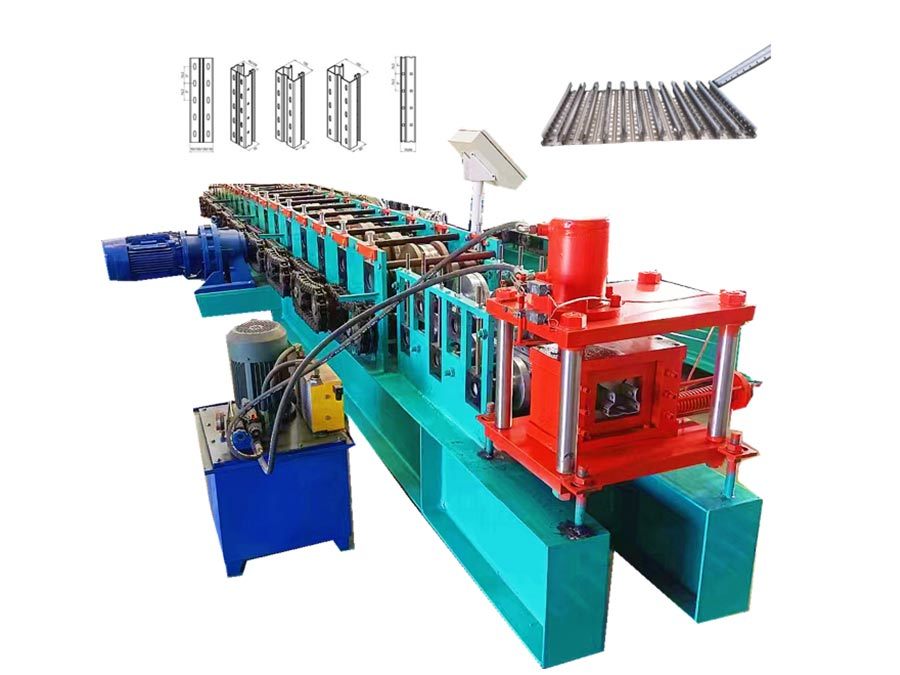

Professional Design Manufacturer for Sales Multi-Size PV U-Bracket Roll Forming Machine for Solar Panel Mounting

Keywords:

Production Equipment

Guangchi Machinery

Category:

Introduction

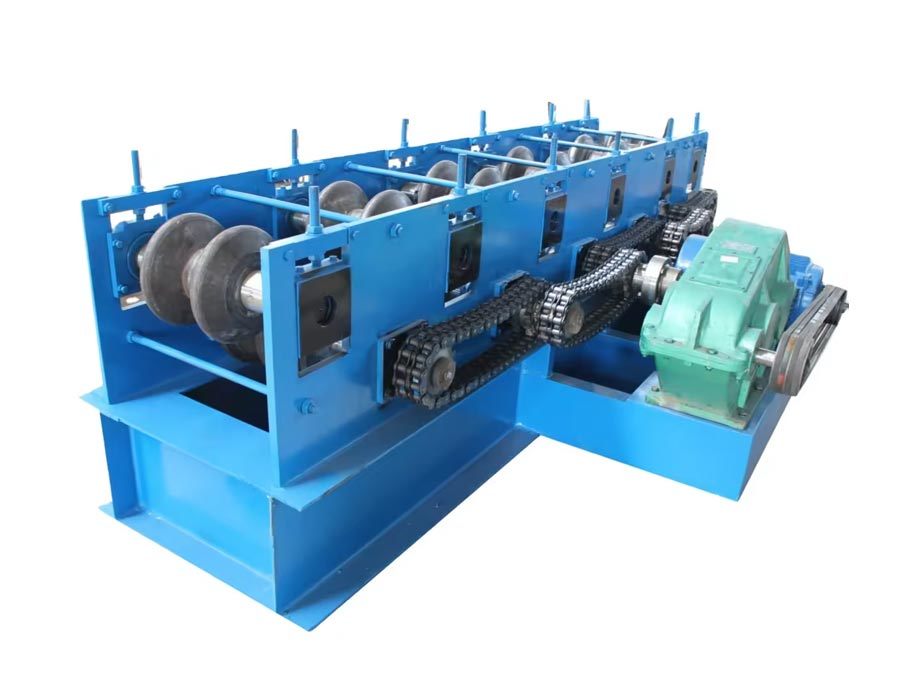

Technical parameters of 25-meter photovoltaic seismic support equipment (gearbox transmission)

1.Shaft diameter Ø80mm, No. 45 quenching and tempering treatment;

2.The thickness of the cast steel arch is 50mm.

3.Double NU212 cylindrical roller bearings.

4.Motor 18.5KW+K97 reducer*2 sets;

5.23 rows of pressure rollers; gearbox drive

6.Main engine power Kaiping (upper 3, lower 4 axles);

7.Cutting is: non-stop flying saw cutting;

8.The electronic control is automatic control by frequency conversion PLC;

9.The roller material is Cr12, vacuum quenched;

10.Correction axis: universal straightening axis;

11.Transmission method: 170 gearbox (8M) transmission;

12.The main frame is welded with steel plate; the thickness of the fuselage plate is 25mm, and the positioning keyway is processed by precision milling.

13.The weight of the main unit is about 13T and the size is about 13mX2.5mX1.1m;

14.Tracking punching and cutting

15.Pressing thickness 2.0-2.75mm

Technical parameters of 40-meter photovoltaic seismic support equipment (gearbox transmission)

1.Shaft diameter Ø80mm, No. 45 quenching and tempering treatment;

2.The thickness of the cast steel arch is 50mm.

3.Double NU212 cylindrical roller bearings.

4.Motor 22KW+K107 reducer*2 sets;

5.23 rows of pressure rollers; gearbox drive

6.Main engine power Kaiping (upper 3, lower 4 axles);

7.Cutting is: non-stop flying saw cutting;

8.The electronic control is automatic control by frequency conversion PLC;

9.The roller material is Cr12, vacuum quenched;

10.Correction axis: universal straightening axis;

11.Transmission method: 170 gearbox (8M) transmission;

12.The main frame is welded with steel plate; the thickness of the fuselage plate is 25mm, and the positioning keyway is processed by precision milling.

13.The weight of the main unit is about 13T and the size is about 15mX2.5mX1.1m;

14.Tracking punching and cutting

15.Pressing thickness 2.0-2.75mm

Advantage

Guangchi Machinery allows you to choose with confidence

Cangzhou Guangchi Machinery co., Ltd. has been engaged in the manufacture of tile press, greenhouse skeleton production equipment,

high-speed guardrail production equipment and other cold-formed molding equipment and products for fifteen years.

Experience

We have nearly 15 years of experience in equipment manufacturing.

Patent

We have our own patented technology and the technology are widely used in this industry.

Quality

We have our own quality inspection team, every machine will be tested and evaluated.

Professionalism

We have a professional design team and over 20 skilled workers.We have 5 engineers to guide the assembly and debugging of the equipment.

Factory

Why choose us?

1. We have factory and provide direct service and lower price.

2. Our boss is a professional designer who graduated from university . She has more than 20 years mechanical design experiences which can provide you professional suggestions about your products, and help you get top sales.

3. We' ve provided kinds of metal machines to many customers including many international trade companies.

Get Quote

*Contact us now, starting from the first communication!