How a Three Beam Guardrail Flattening Machine Enhances Manufacturing Efficiency

2025-04-16

How a Three Beam Guardrail Flattening Machine Enhances Manufacturing Efficiency

Manufacturing efficiency is paramount in today’s competitive industrial landscape. Among the various tools that can significantly affect efficiency, the **Three Beam Guardrail Flattening Machine** stands out. Its innovative design and functionality not only streamline the production process but also enhance the overall

How a Three Beam Guardrail Flattening Machine Enhances Manufacturing Efficiency

Manufacturing efficiency is paramount in today’s competitive industrial landscape. Among the various tools that can significantly affect efficiency, the **Three Beam Guardrail Flattening Machine** stands out. Its innovative design and functionality not only streamline the production process but also enhance the overall quality of metal products. This article explores the mechanics, benefits, and technological advancements associated with this vital piece of machinery.

Table of Contents

1. Introduction to Three Beam Guardrail Flattening Machines

2. Key Features of the Three Beam Guardrail Flattening Machine

3. How the Machine Works: A Detailed Overview

4. The Advantages of Using a Three Beam Guardrail Flattening Machine

5. Enhancing Production Efficiency Through Automation

6. Comparing Traditional Methods vs. Modern Solutions

7. Case Studies: Real-World Applications and Success Stories

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Introduction to Three Beam Guardrail Flattening Machines

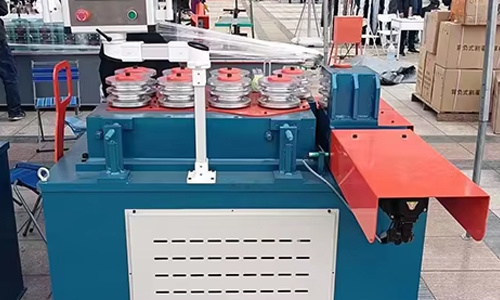

The **Three Beam Guardrail Flattening Machine** is designed specifically for processing road guardrails and other metallic components. Its primary function is to flatten three beams simultaneously, ensuring a consistent and high-quality product. In the realm of **manufacturing machinery**, this equipment represents a significant investment for companies looking to maximize efficiency and output.

2. Key Features of the Three Beam Guardrail Flattening Machine

Understanding the features of the Three Beam Guardrail Flattening Machine is essential for appreciating its role in enhancing manufacturing efficiency. Here are some of its standout features:

2.1 High Throughput Capacity

With the ability to process multiple beams in a single cycle, the machine drastically reduces production time and labor costs.

2.2 Precision Engineering

The machine incorporates advanced technology that ensures precision flattening, minimizing wastage and rework.

2.3 User-Friendly Interface

Operators can easily navigate and control the machine through a simple interface, reducing training time and increasing productivity.

2.4 Robust Construction

Built to withstand the rigors of industrial use, the durable design of the machine ensures longevity and reliability.

3. How the Machine Works: A Detailed Overview

To understand the operational mechanics of the Three Beam Guardrail Flattening Machine, it's crucial to look at its process.

3.1 Loading the Material

The process begins with the operator loading the metal beams into the machine. The fixture holds the beams securely in place.

3.2 Initial Adjustment Settings

Before commencing, operators select the desired flattening specifications through the digital control panel, ensuring the right settings for the specific type of beam.

3.3 Flattening Process

Once initiated, the machine applies a calculated amount of force to flatten the beams evenly. This process employs hydraulic systems, which provide the necessary pressure while maintaining accuracy.

3.4 Quality Control

After the flattening process, a quick inspection is conducted to ensure each beam meets the required specifications. Any defective units can be easily identified and removed from the batch.

4. The Advantages of Using a Three Beam Guardrail Flattening Machine

Utilizing a Three Beam Guardrail Flattening Machine presents numerous advantages that contribute to improved manufacturing efficiency.

4.1 Time Savings

The ability to flatten three beams simultaneously means that production rates can significantly increase, allowing manufacturers to meet higher demand without sacrificing quality.

4.2 Cost Efficiency

Reduced labor costs and lower material waste lead to considerable savings, enhancing the overall profitability of the manufacturing process.

4.3 Enhanced Product Quality

The precision of the flattening process ensures that every finished product adheres to strict quality standards, improving customer satisfaction and reducing returns.

4.4 Increased Safety Standards

By employing machines for repetitive tasks, the risks associated with manual labor decrease, leading to a safer work environment.

5. Enhancing Production Efficiency Through Automation

Automation plays a critical role in the performance of the Three Beam Guardrail Flattening Machine. This section explores how automation contributes to manufacturing efficiency.

5.1 Streamlined Workflows

The integration of automated features eliminates bottlenecks in the production line, enabling a smoother workflow.

5.2 Reduced Human Error

Automated systems minimize the risk of human error, ensuring consistent and reliable output.

5.3 Data Monitoring and Analysis

Modern machines often come equipped with data-logging capabilities, allowing manufacturers to monitor production metrics in real-time, identify inefficiencies, and make informed decisions.

6. Comparing Traditional Methods vs. Modern Solutions

To appreciate the benefits of the Three Beam Guardrail Flattening Machine, we must compare it to traditional manufacturing methods.

6.1 Manual Labor vs. Machine Efficiency

While traditional methods rely heavily on manual labor, the use of flattening machines automates the process, saving time and improving accuracy.

6.2 Cost Implications

Although traditional methods may seem less costly initially, the long-term benefits of investing in a flattening machine outweigh the upfront expenses regarding efficiency and output.

6.3 Quality Consistency

Manual methods often lead to variations in quality. In contrast, machines guarantee uniformity, ensuring every product meets standards.

7. Case Studies: Real-World Applications and Success Stories

Examining real-world applications can shed light on how the Three Beam Guardrail Flattening Machine has transformed operations in various companies.

7.1 Case Study 1: ABC Manufacturing Co.

ABC Manufacturing Co. implemented the flattening machine in their production line, resulting in a **30% increase in output** while reducing labor costs by **20%**.

7.2 Case Study 2: XYZ Industries

XYZ Industries adopted the technology and noted a **40% reduction in material waste**, showcasing the machine's ability to enhance efficiency and sustainability.

8. Frequently Asked Questions (FAQs)

8.1 What is a Three Beam Guardrail Flattening Machine?

A Three Beam Guardrail Flattening Machine is a specialized piece of equipment designed to flatten three beams simultaneously, enhancing production efficiency in metal processing.

8.2 How does the machine improve manufacturing efficiency?

By automating the flattening process, the machine minimizes labor costs, reduces production time, and ensures consistent quality.

8.3 What industries benefit from this machine?

Industries involved in metal fabrication, particularly those dealing with road safety equipment, benefit greatly from this technology.

8.4 Is the machine easy to operate?

Yes, the user-friendly interface allows operators to quickly learn and efficiently manage the machine.

8.5 What maintenance is required for the machine?

Regular maintenance involves inspecting hydraulic systems and ensuring the machine is calibrated correctly to maintain optimal performance.

9. Conclusion

The **Three Beam Guardrail Flattening Machine** is a game-changer in the manufacturing sector, notably for companies focused on metal processing. Its ability to automate processes, enhance product quality, and improve operational efficiency makes it an invaluable asset. As industries continue to seek ways to streamline operations and reduce costs, investing in such advanced machinery will undoubtedly yield significant long-term benefits. By leveraging the capabilities of the Three Beam Guardrail Flattening Machine, manufacturers can stay ahead of the competition and achieve sustained growth in an increasingly demanding market.

Key words:

Wholesale Three beam guardrail flattening machine Price

RELATED INFORMATION

A customer from Inekhusko, Russia, took a 10-hour flight with multiple transfers to visit our factory and inspect the equipment they had previously ordered from our company.Our foreign trade staff warmly received the customer.

2025-04-24

Photovoltaic bracket equipment is a special bracket planned for the placement, installation.

2024-05-22

The control method of greenhouse pipe bender and the CNC processing of pipe bender

The greenhouse pipe bender has a fuel tank cap. We can take advantage of the environment where the oil in.

2024-05-22