Contact Us

Electronic E-mail

info@gcrollforming.com

Telephone:

+8615233789270

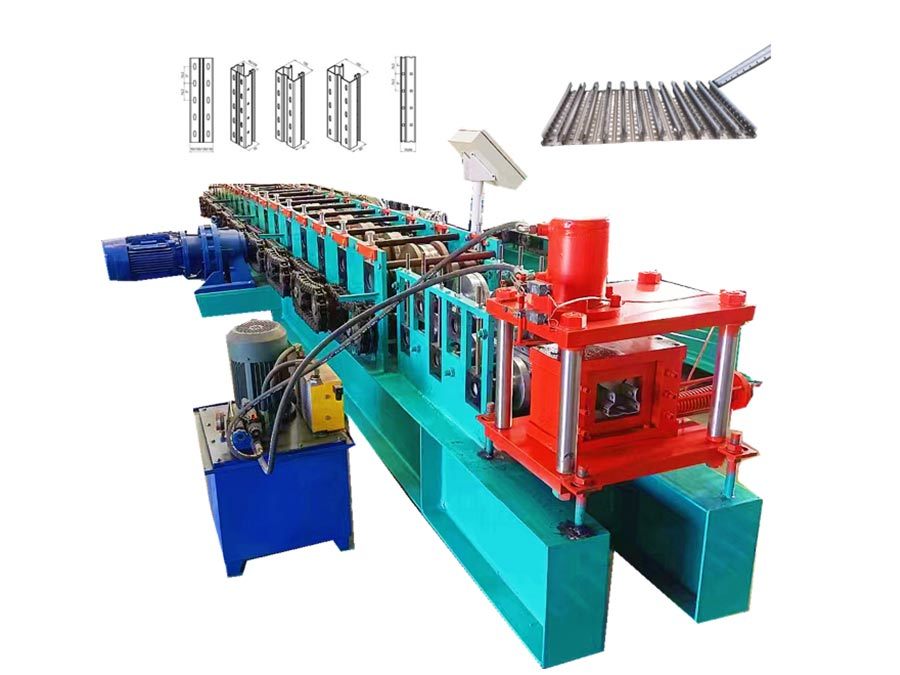

Rolling door forming machine

Keywords:

Category:

Introduction

|

Roller shutter door panel roll forming machine |

|

|

Forming size |

180*17mm |

|

Forming row |

15 |

|

Shaft diameter |

Ø70mm |

|

Shaft material |

45# |

|

Roll material |

Cr12 |

|

Main power |

11KW+K87 reducer |

|

Control system |

Automatic computer control |

|

Frame |

Steel welding |

|

Transmission way |

By 1.5inch chain |

|

Hydraulic power |

4KW |

|

Voltage |

380v 50hz, 3phrase |

|

Decoiler |

3T |

|

Cutting way |

Hydraulic |

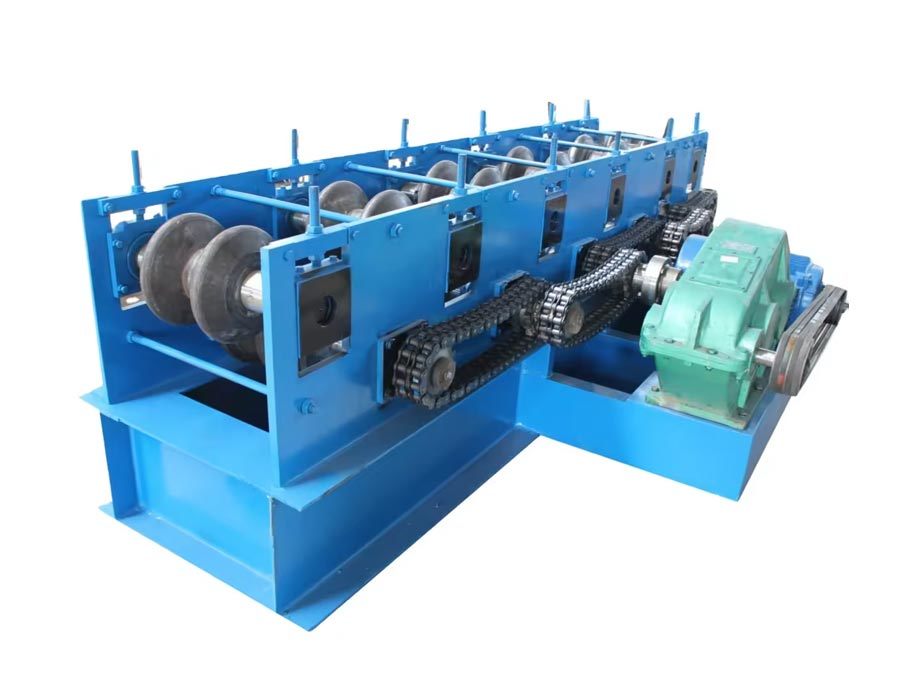

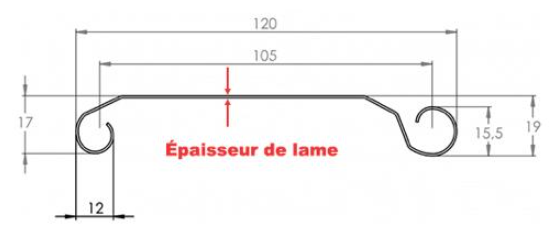

| 160 curtain machine technical parameters: | |

| Note: It is quickly interchangeable with the negative film curtain machine | |

| Size |

120*19mm |

| Number of roll forming rows | 14 rows |

| Cut off | Cut off with holes |

| Embossing | With embossing wheel |

|

Straightening |

Install straightening wheel at the discharge port |

|

Processing thickness |

0.5-0.8mm |

|

Roller shaft diameter |

Ø50 |

|

Shaft Material |

45# quenching and tempering, fine turning, fine grinding |

|

Wheel material |

Cr12 quenching, fine turning, fine grinding |

|

Archway |

Bull Foundry Archway |

|

Transmission mode |

1 inch chain drive |

|

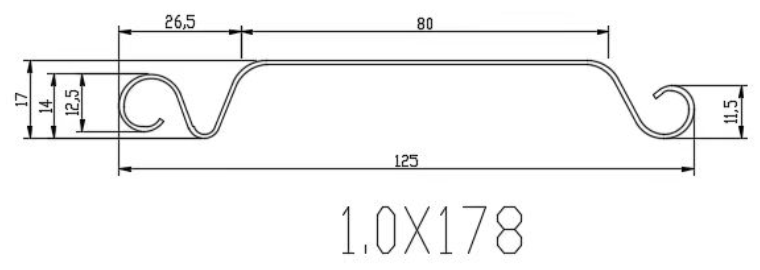

178 curtain machine technical parameters: |

|

|

Note: Quickly interchange with the film curtain machine |

|

|

size |

120*19mm |

|

Roller forming row number |

14 rows |

|

Cut off |

Cutting hole |

|

Straightening |

Install straightening wheel at the discharge port |

|

Processing thickness |

0.5-1.2mm |

|

Roller shaft diameter |

Ø50 |

|

Shaft Material |

45# quenching and tempering, fine turning, fine grinding |

|

Wheel material |

Cr12 quenching, fine turning, fine grinding |

|

Archway |

Bull Foundry Archway |

|

Transmission mode |

1.2 inch chain drive |

|

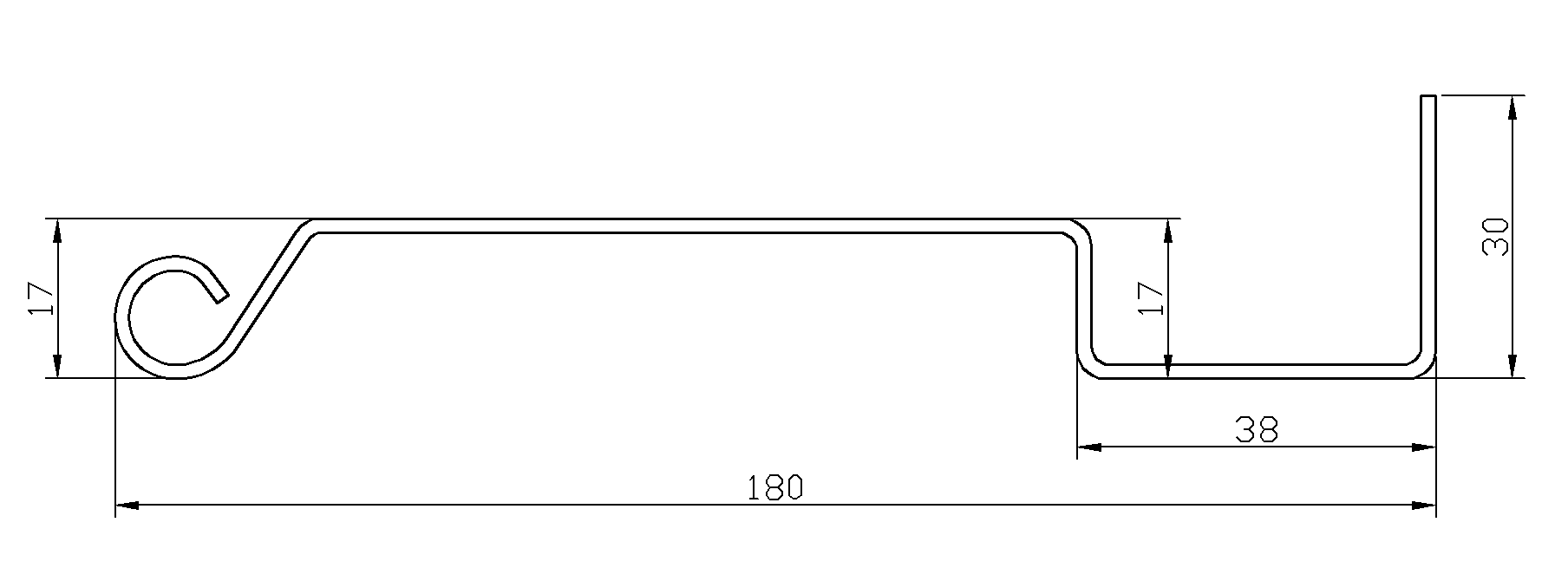

U-shaped guide rail technical parameters: |

|

|

size |

40/60/80/100*30mm |

|

Roller forming row number |

10 rows |

|

Straightening |

Install straightening wheel at the discharge port |

|

Processing thickness |

1.5-2.5mm |

|

Roller shaft diameter |

Ø70 |

|

Shaft Material |

45# quenching and tempering, fine turning, fine grinding |

|

Wheel material |

Cr12 quenching, fine turning, fine grinding |

|

Host power |

11KW+K87 reducer |

|

Control System |

Computer automatic control |

|

frame |

Steel plate welding, surface flat plate milling |

|

Archway |

Bull Foundry Archway |

|

Transmission mode |

1.5 inch chain drive |

|

Pumping Station |

4KW large fuel tank with fan |

|

Cut off |

Hydraulic mold shutdown cut-off |

|

appendix |

With a 3-ton single-arm manual loading rack |

Advantage

Guangchi Machinery allows you to choose with confidence

Cangzhou Guangchi Machinery co., Ltd. has been engaged in the manufacture of tile press, greenhouse skeleton production equipment,

high-speed guardrail production equipment and other cold-formed molding equipment and products for fifteen years.

Experience

We have nearly 15 years of experience in equipment manufacturing.

Patent

We have our own patented technology and the technology are widely used in this industry.

Quality

We have our own quality inspection team, every machine will be tested and evaluated.

Professionalism

We have a professional design team and over 20 skilled workers.We have 5 engineers to guide the assembly and debugging of the equipment.

Factory

Why choose us?

1. We have factory and provide direct service and lower price.

2. Our boss is a professional designer who graduated from university . She has more than 20 years mechanical design experiences which can provide you professional suggestions about your products, and help you get top sales.

3. We' ve provided kinds of metal machines to many customers including many international trade companies.

Previous:

Next:

Get Quote

*Contact us now, starting from the first communication!