Contact Us

Electronic E-mail

info@gcrollforming.com

Telephone:

+8615233789270

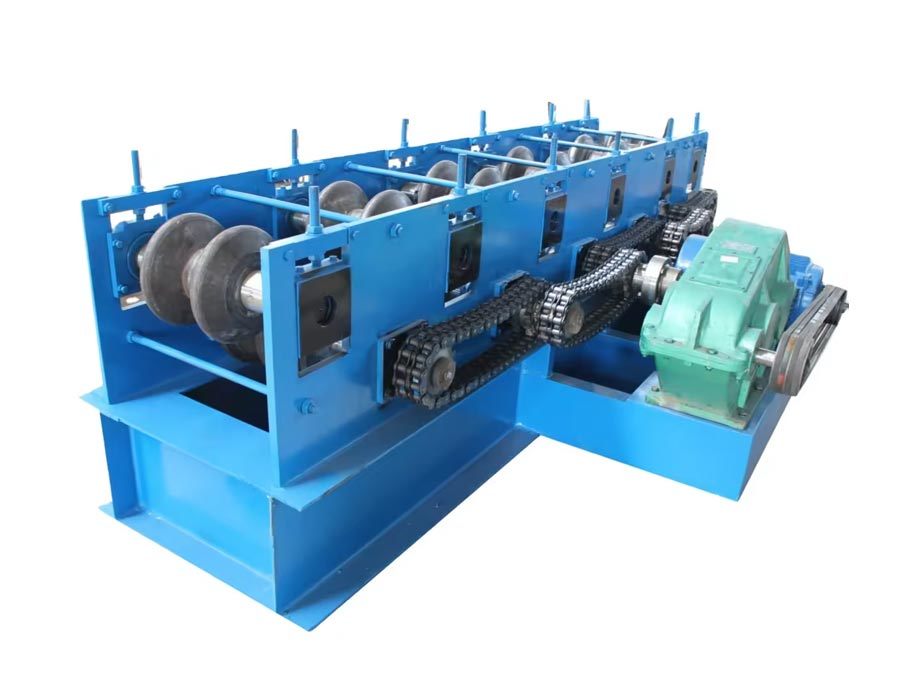

Pipe and tube bending machine

Keywords:

Production Equipment

Guangchi Machinery

wholesale Pipe and tube bending machine suppliers

Category:

Introduction

|

Parameters of nine-wheel CNC pipe bender

(double servo high configuration)

|

||

|

Equipment size

|

About 1.5m*1.4m*1.4m

|

Size and weight: about 1.5t according to the

actual finished product

|

|

Plant capacity

|

Transmission servo motor 5.4 Kw, push-bending servo motor 3.8kw, servo motor

equipped with fuel-free precision reducer, working voltage of 380V, Shenzhen

sinusoidal servo motor

|

|

|

Working shaft

|

Shaft diameter 70mm, solid shaft. Material: 45 # steel

|

|

|

The bench panel is

thick

|

40mm top top frame for 50 * 100 square pipe welding

|

|

|

Mold wheel

|

45 # steel quenching, fine car, plating, wheel outer diameter 180mm

|

|

|

Control system

|

Zhongbo CNC electronic control system, Delta PLC, three crystal frequency

converter, liquid crystal display, according to different customers different radian

storage data, different radian replacement, the system and servo motor low

temperature resistance and high temperature good effect, less affected by the external

temperature and humidity changes, to ensure the bending effect consistent error is

small.

|

|

|

Production

specifications

|

According to the customer's selected model, the main machine has two models of

molds (one set of molds), add another set of mold 300USD, and one set of molds

can produce two size models.

|

|

|

Production speed and

raw material

adaptation thickness

|

Speed of 35-60 / min, adjustable speed, adapted to the raw material thickness of

3.0mm and below

|

|

|

Driving mode

|

Bilateral gear 8 wheel transmission, each drive shaft has a gear connection motor,

servo motor ball wire rod straight guide rail push bending, accurate radian.

|

|

|

Pprice

|

5800USD /SET (EXW)

|

|

|

Parameters of nine-wheel CNC pipe bender

(medium configuration)

|

||

|

Equipment size

|

About 1.5m*1.4m*1.4m

|

Size and weight: about 1.5t according to the

actual finished product

|

|

Plant capacity

|

7.5 Kw, push-bending servo motor 3.8 kW, servo motor is equipped with fuel-free

precision reducer, working voltage is 380V, Shenzhen sinusoidal servo motor

|

|

|

Working shaft

|

Shaft diameter 70mm, solid shaft. Material: 45 # steel

|

|

|

The bench panel is

thick

|

40mm top top frame for 50 * 100 square pipe welding

|

|

|

Mold wheel

|

45 # steel quenching, fine car, plating, wheel outer diameter 180mm

|

|

|

Control system

|

Zhongbo CNC electronic control system, Delta PLC, three crystal frequency

converter, liquid crystal display, according to different customers different radian

storage data, different radian replacement, the system and servo motor low

temperature resistance and high temperature good effect, less affected by the external

temperature and humidity changes, to ensure the bending effect consistent error is

small.

|

|

|

Production

specifications

|

According to the customer's selected model, the main machine has two models of

molds (one set of molds), add another set of mold 300USD, and one set of molds

can produce two size models.

|

|

|

Production speed and

raw material

adaptation thickness

|

Speed of 35-60 / min, adjustable speed, adapted to the raw material thickness of

3.0mm and below

|

|

|

Driving mode

|

Bilateral gear 8 wheel transmission, each drive shaft has a gear connection motor,

servo motor ball wire rod straight guide rail push bending, accurate radian.

|

|

|

Price

|

5200USD /SET (EXW)

|

|

|

Parameters of nine-wheel CNC pipe bender

(standard)

|

||

|

Equipment size

|

About 1.5m*1.4m*1.4m

|

Size and weight: about 1.2t according to the

actual finished product

|

|

Plant capacity

|

Transmission planetary cycloid motor 7.5 Kw, push bending servo motor 3.8 kW,

servo motor equipped with fuel-free precision reducer, working voltage of 380V,

Shenzhen sinusoidal servo motor

|

|

|

Working shaft

|

Shaft diameter 55mm, solid shaft. Material: 45 # steel

|

|

|

The bench panel is

thick

|

30mm top table is milled, large frame for 50 * 100 square pipe welding.

|

|

|

Mold wheel

|

45 # steel quenching, fine car, plating luo, wheel outer diameter 160mm

|

|

|

Control system

|

Zhongbo CNC electronic control system, Delta PLC, three crystal frequency

converter, liquid crystal display, according to different customers different radian

storage data, different radian replacement, the system and servo motor low

temperature resistance and high temperature good effect, less affected by the external

temperature and humidity changes, to ensure the bending effect consistent error is

small.

|

|

|

Production

specifications

|

According to the customer's choice model, the main factory with two models of mold

(a set of mold), add another set of mold 300USD, a set of mold can be out of two

size models.

|

|

|

Production speed and

raw material

adaptation thickness

|

Speed of 10-25 / min, adjustable speed, suitable for raw material thickness of 3.0mm

and below

|

|

|

Driving mode

|

Bilateral gear 8 wheel transmission, each drive shaft has a gear connection motor,

servo motor ball wire rod straight guide rail push bending, accurate radian.

|

|

|

Equipment price

|

5000/SET (EXW)

|

|

Advantage

Guangchi Machinery allows you to choose with confidence

Cangzhou Guangchi Machinery co., Ltd. has been engaged in the manufacture of tile press, greenhouse skeleton production equipment,

high-speed guardrail production equipment and other cold-formed molding equipment and products for fifteen years.

Experience

We have nearly 15 years of experience in equipment manufacturing.

Patent

We have our own patented technology and the technology are widely used in this industry.

Quality

We have our own quality inspection team, every machine will be tested and evaluated.

Professionalism

We have a professional design team and over 20 skilled workers.We have 5 engineers to guide the assembly and debugging of the equipment.

Factory

Why choose us?

1. We have factory and provide direct service and lower price.

2. Our boss is a professional designer who graduated from university . She has more than 20 years mechanical design experiences which can provide you professional suggestions about your products, and help you get top sales.

3. We' ve provided kinds of metal machines to many customers including many international trade companies.

Previous:

Get Quote

*Contact us now, starting from the first communication!